4000 Retrofit Sliding Device

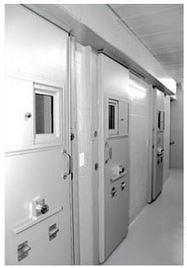

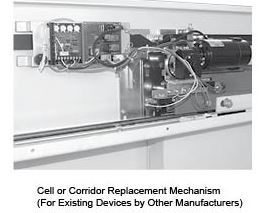

The 4000 is a motorized locking device mechanism designed to replace the interior components of existing cell, multiple cell or inmate room sliding devices of other manufacturers. The unit is designed to replace Corridor, Entrance, Sallyport and Cell Doors, while in most cases using the existing housing, door, receiver, release column, vertical locking column, and guides.

The 4000 is a motorized locking device mechanism designed to replace the interior components of existing cell, multiple cell or inmate room sliding devices of other manufacturers. The unit is designed to replace Corridor, Entrance, Sallyport and Cell Doors, while in most cases using the existing housing, door, receiver, release column, vertical locking column, and guides.Description

⊡ Retro Slider

⊡ Rack & Pinion Drive

⊡ Maximum Security

Power Variations

⊡ 120 VAC Gear Motor

⊡ 230 VAC Gear Motor

⊡ 24 VDC Gear Motor

Features

⊡ Non-Handed Mechanism

⊡ Modular Components

⊡ Gear Motor Unlocking w/ Spring Open Release

⊡ 2 Point Rear Deadlocking (Where Applicable)

⊡ Door Position Indicator

⊡ Deadlock Position Indicator

⊡ Emergency Manual Release

⊡ Easy Connect Field Wiring

Options

⊡ Mechanical and/or Electric Key Release by (One) Paracentric Key in Release Column

⊡ Mechanical and/or Electric Key Release by (One) Mogul Cylinder in Release Column

⊡ Custom Controls - Graphics - PLC - Multiplex - Touch Screen - Hard Wire

Operation

Unit opens and closes electrically while deadlocking in each direction. If stopped in mid-travel, the door is back-drivable. Unit may be instantly reversed. Door blockage will not cause motor damage. Door pressure is adjustable from approximately 40 lbs. Emergency release allows the door to be moved against slight motor pressure and is never free-wheeling.

Function

The 4000 Retro Device is a motor- ized mechanism designed to re- place the interior components of existing wornout sliding devices of other manufacturers.

The door is powered by means of push buttons or a selector switch. When the door is opened or closed, it may be stopped in mid-travel. During that period, the door may be manually moved open or closed by applying a slight force on the door. The door may also be instantly reversed without any harm to the mechanism.

Upon fully opening or closing, the door is locked at two concealed points at the vertical lock column. The locking rod is also fully deadlocked preventing the rod from being manipulated. No locking components are exposed.

During a power loss, the 4000 may be mechanically released by key, at which point the door may be moved to an open or closed position. The door is never freewheeling.

The 4000 device has been rigorously tested to over 500,000 cycles.

Retro-Fit Modifications

The existing housing, cover, door, vertical lock column, release column and guides (where applicable) are re-used to provide substantial cost savings.

Electro/Mechanical Drive System

⊡ Non-Handed - Easy Access 10" x 10¾" Mechanism Assy

⊡ All Mechanism Assy Parts - Corrosive Resistant Materials

⊡ Gear Motor - 120 VAC, 60 Hz

⊡ Gear Motor - 230 VAC, 50/60 Hz

⊡ Gear Motor - 24 VDC

⊡ 1" x 5/8" Rack & Pinion 14½ Degree Spur Gear w/ #10 Pitch

⊡ 1/11 HP 90VDC Variable Speed Motor - 120VAC Power Source

⊡ Electronically Controlled Adjustable Door Pressure

⊡ Logic Board Allows a Variety of Control Voltages

⊡ Modular Easy Access Motor and Indicator Limit Switches

⊡ Easy Access Motor Drive and Logic Board

Structural Components

⊡ ¼" Door Hanger, Door Angle and Door Guide

⊡ 3/8" Front and Rear Carriage Plates

⊡ 9/16" CRS 1045 High Carbon Track

⊡ Steel Rollers with Ball Bearings attached with ½" Dia. HHCS

Mechanical Release Mechanism

⊡ Use of Existing Lock

⊡ Paracentric Deadbolt in Housing or Existing Release Column